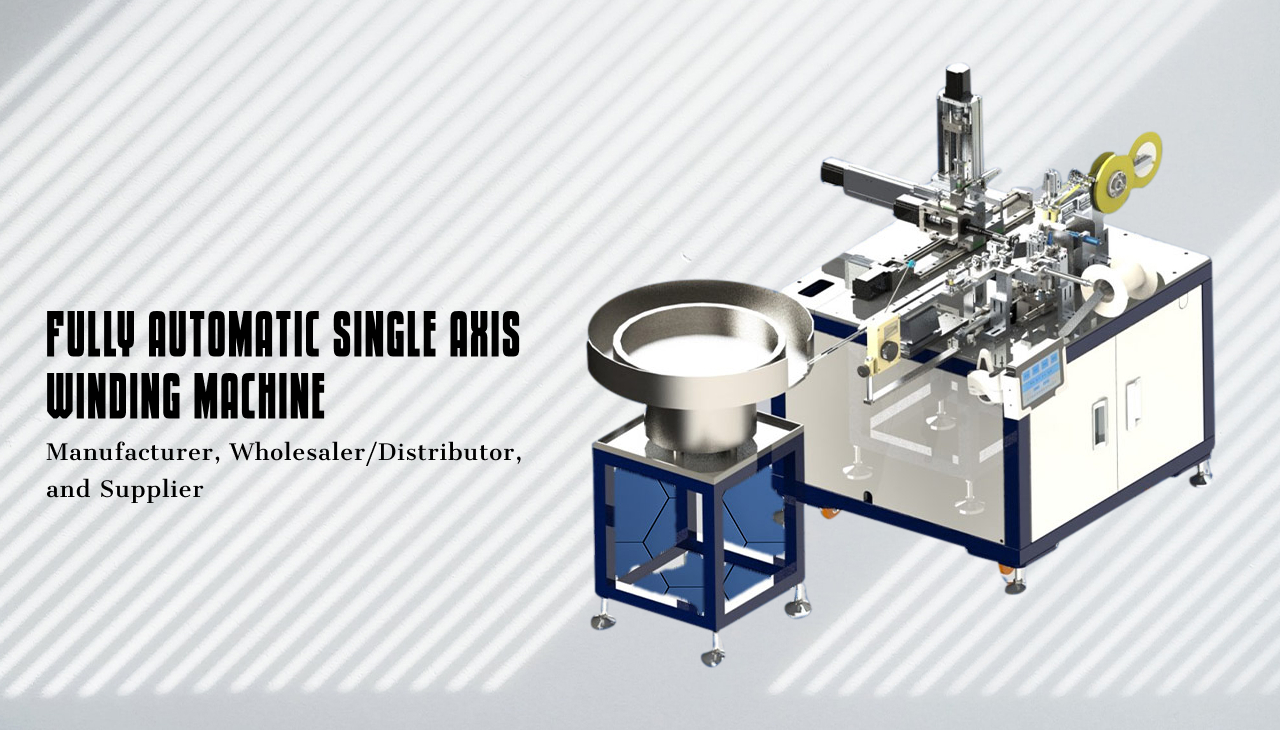

Closed Loop Tensioner Controller

Product Details:

- Product Type Tensioner Controller

- General Use Maintaining Consistent Tension in Winding Applications

- Material Mild Steel, Aluminum Body

- Type Automatic Controller Unit

- Weight (kg) 8-12 kg

- Computerized Yes

- Automatic Yes

- Click to View more

Closed Loop Tensioner Controller Product Specifications

- Grey

- Up to 300 mm

- 8-12 kg

- Single/Double

- 4-6 Bar

- Up to 3000 rpm

- Maintaining Consistent Tension in Winding Applications

- Electric

- Mild Steel, Aluminum Body

- Automatic Controller Unit

- Closed Loop Feedback Control

- 50-150W

- Yes

- 220V/240V AC

- Tensioner Controller

- Servo Motor Driven

- Real-Time Tension Control, LCD Display, User Programmable

- 320 x 210 x 140 mm

- Yes

- High Precision Spindle

- 0.5%

- Panel/Wall Mount

- 0.1 mm 2.0 mm

- <50 ms

- RS485/Modbus

- 0C to 50C

- Load Cell based

- Analog/Encoder

- Digital LCD

- Audio Visual Alarm for Faults

- 0.1N to 20N

- Available

- Natural Air Cooled

Product Description

CLOSED LOOP TENSIONER CONTROLLER

CLOSED LOOP TENSION CONTROLLER CTK SERIES

CTK Controllers are closed loop tension measurement and control instruments, designed to be used with a hysteresis brake or to act as a monitoring tension meter.

The PLC Control closed-loop type allows for interacting with PLC and providing required current to the hysteresis brake.

Closed Loop Type :

This Model measures and displays real-time running tension, while simultaneously comparing it to the preset tension values. Its Built in software compensates output current to the hysteresis brake accordingly for precise, stable and consistent tension.

Stand-Alone Type :

This model does not provide current output. They are used to measure and display real time tension.

It also alerts (output alarm) the user when tension is detected to be out of preset range (the upper and lower tension limits can be preset).

BASIC SPECIFICATIONS OF CTK CONTROLLERS

| PLC Control Closed Loop Type | Closed Loop Type | Stand Alone Type | Applicable Tension Range (grms) |

| CTK-5000-WMB01 | CTK-5000-WAB01 | CTK-5000-W | 0g-5000g |

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Real-Time Digital Control for Winding Applications

Experience precise, real-time control and monitoring with the Closed Loop Tensioner Controller's digital LCD interface. The programmable tension system maintains consistent winding, supporting varied coil diameters up to 300 mm and wire diameters from 0.1 mm to 2.0 mm. Designed for both single and double winding heads, users benefit from intuitive adjustments and instant feedback, ensuring quality and repeatability in winding processes.

Reliable Performance and Enhanced Safety

Equipped with overload protection and an audio-visual alarm system, the controller offers operational safety and minimizes risks in demanding environments. The closed loop feedback mechanism maintains tension accuracies within 0.5%, while rapid response allows for high-speed winding (up to 3000 rpm) without compromising control. The robust construction and air-cooled system add further reliability for industrial use.

Flexible Integration and User Programmability

RS485/Modbus connectivity makes this tensioner controller easy to integrate into existing automation systems. Input signal compatibility with analog or encoder sources and user-programmable settings allow for customization to various winding needs. The compact, panel or wall-mounted design ensures straightforward installation and operation within temperature ranges from 0C to 50C.

FAQ's of Closed Loop Tensioner Controller:

Q: How does the Closed Loop Tensioner Controller improve winding consistency?

A: The controller utilizes closed loop feedback with a load cell-based sensor to automatically adjust and maintain set tensions, resulting in consistent coil winding and reduced defects. Real-time monitoring through the digital LCD ensures immediate display of tension status and diagnostic feedback.Q: What is the process for configuring tension settings on the controller?

A: Users can set precise tension values from 0.1N to 20N using the digital LCD interface. The device supports both analog and encoder inputs for flexibility, and its user programmable function allows for tailored adjustments suited to specific wire diameters and coil sizes.Q: When should overload protection and alarm systems be utilized?

A: Overload protection and audio-visual alarms automatically activate whenever a fault, excessive tension, or unsafe operating condition is detected, protecting both the equipment and winding material. Routine monitoring during operation helps maintain safe and reliable performance.Q: Where can the controller be mounted for best performance?

A: The tensioner controller can be installed on panels or walls, making it suitable for various industrial settings such as manufacturing floors and winding stations. Its compact dimension (320 x 210 x 140 mm) and durable build enable seamless integration into existing equipment layouts.Q: What are the benefits of RS485/Modbus communication interface?

A: RS485/Modbus enables fast, reliable data communication with supervisory control systems or production networks. This facilitates remote monitoring, parameter adjustment, and integration with other automated processes, enhancing operational efficiency and control.Q: How is the controller cooled during operation?

A: The device uses a natural air cooling system, which maintains optimal operating temperatures during continuous use without requiring additional cooling infrastructure. This design contributes to long-term durability and trouble-free operation in diverse environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Closed Loop Tensioners' category

|

TROPHY TECH INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |