Ceramic Eyelet/Ceramic Bush/Ceramic Ring

Product Details:

- Material Ceramic

- Shape Eyelet, Bush, Ring

- Pattern Smooth/Polished

- Size Standard/Custom

- Color Pink and White

- Click to View more

Ceramic Eyelet/Ceramic Bush/Ceramic Ring Price And Quantity

- 1 Unit

- INR

- Superior

- High

- Excellent

- For Winding Machine

- Textile Machinery

- 50-100 g

- Low/Zero

- Glazed

- Eyelet, Bush and Ring

Ceramic Eyelet/Ceramic Bush/Ceramic Ring Product Specifications

- Smooth/Polished

- Eyelet, Bush, Ring

- Standard/Custom

- Pink and White

- Ceramic

- Superior

- High

- Excellent

- For Winding Machine

- Textile Machinery

- 50-100 g

- Low/Zero

- Glazed

- Eyelet, Bush and Ring

Ceramic Eyelet/Ceramic Bush/Ceramic Ring Trade Information

- 2000 Unit Per Month

- 3-4 Week

- All India

Product Description

Ceramic Rings has been used for guiding the direction. The ceramic ring, which has been made of nice ceramic, the Luster degree of its working side attains Ra 0.2. Because of the high hardness and the rough degree, the surface of ceramic ring is very smooth and the friction coefficient is very low, it can act as guide apparatus to the part winch is not important so that even the wire is slipping on its surface, it won't be scatted.

TROPHY's ceramic eyelets are made of 99% Alumina AI203, a material with HRA88 hardness and a density of 3.85. Surfaces are polished to ultra-fine finish of Ra 0.2.

We can also polish the ceramic eyelet according to the users requirement, such as a surface finish with semi-polished (Ra 0.8) and fine polished (Ra 0.4).

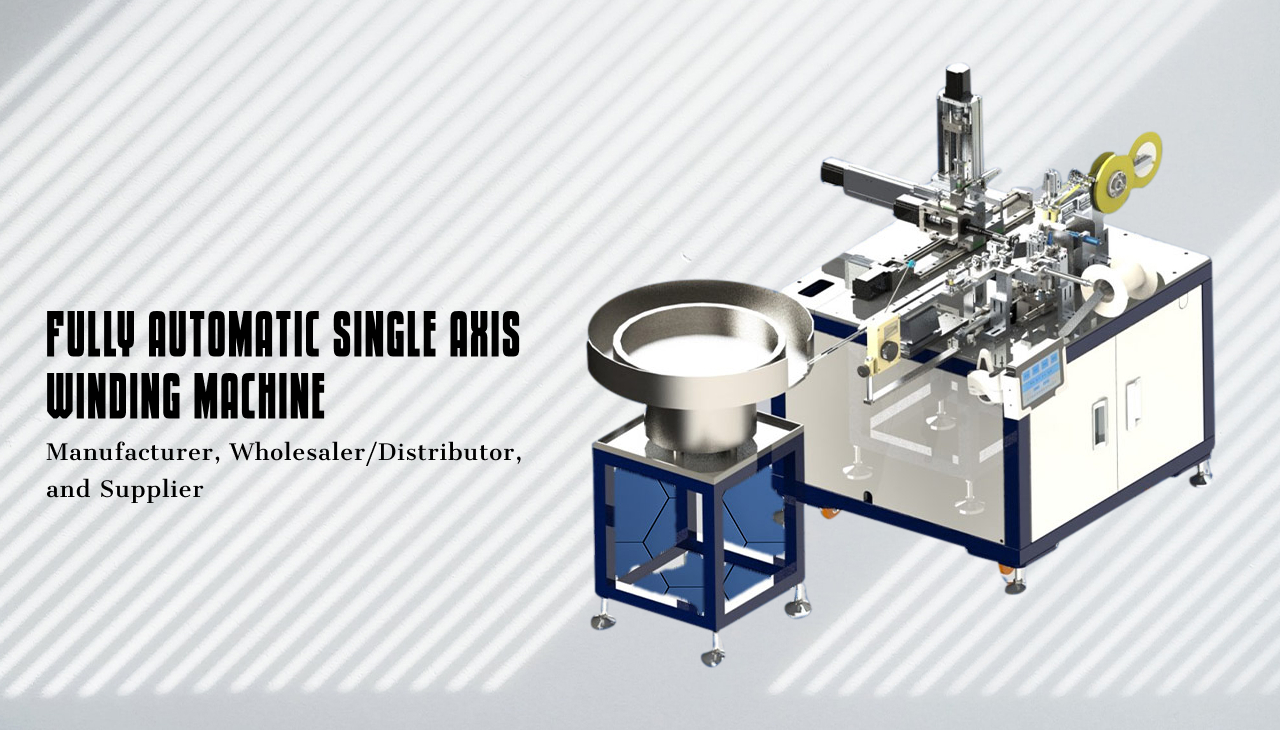

The table below shows the commonly used specifications of ceramic eyelets.

Technical Specifications

| Model | D1 | D2 | d | H | H1 |

| CY-001AW | 4.5 | 2.8 | 1.0 | 3.0 | 1.0 |

| CY-002AW | 5.0 | 3.5 | 2.4 | 3.6 | 1.0 |

| CY-003AW | 6.7 | 4.7 | 2.6 | 3.2 | 1.2 |

| CY-004AW | 10.0 | 7.2 | 4.8 | 8.6 | 1.6 |

| CY-005AW | 10.0 | 7.0 | 4.8 | 8.6 | 1.6 |

| CY-006AW | 11.0 | 8.0 | 3.6 | 9.0 | 3.0 |

| CY-007AW | 7.8 | 5.2 | 3.0 | 5.3 | 1.5 |

Exceptional Wear Resistance and Durability

Ceramic eyelets, bushes, and rings offer superior wear resistance, making them ideal for continuous use in textile winding machines. Their robust nature provides extended service life and minimizes the need for frequent replacement, which ultimately helps to reduce maintenance costs.

High Temperature and Electrical Insulation

Manufactured from premium ceramic material, these components withstand high operating temperatures and exhibit outstanding electrical insulating properties. Their low porosity and glazed surface ensure stability and safety, even in challenging industrial environments.

Customizable to Your Application Needs

Ceramic eyelets, bushes, and rings are available in both standard and custom dimensions to fit specific machinery requirements. Their smooth, polished pattern not only enhances process accuracy but also ensures minimal fiber damage during textile manufacturing.

FAQs of Ceramic Eyelet/Ceramic Bush/Ceramic Ring:

Q: How are ceramic eyelets, bushes, and rings used in winding machines?

A: These ceramic components guide and protect threads during the winding process, ensuring smooth and accurate handling within textile machinery. Their superior wear resistance and polished finish help prevent thread breakage and reduce friction.Q: What benefits do ceramic parts provide for textile machinery operations?

A: Ceramic eyelets, bushes, and rings offer high temperature resistance, excellent electrical insulation, and low porosity, leading to improved safety, performance efficiency, and longevity of equipment in textile manufacturing environments.Q: When should I choose pink or white ceramic components?

A: Both pink and white options are made from high-grade ceramic materials and provide similar technical properties. The choice often depends on aesthetic preference or existing machinery color schemes, as both colors ensure optimum functionality.Q: Where can I source these ceramic eyelets, bushes, and rings in India?

A: You can obtain these components directly from manufacturers, suppliers, or distributors specializing in ceramic products for textile machinery throughout India. Custom orders are typically available to match specific sizing and pattern requirements.Q: What is the manufacturing process for these ceramic components?

A: Ceramic eyelets, bushes, and rings are produced through precision molding, firing, glazing, and polishing processes. This results in dense, smooth, and highly durable parts suitable for textile machinery applications.Q: Can these ceramic parts be customized to fit specific textile machines?

A: Yes, manufacturers provide standard and custom sizing options to ensure seamless compatibility with various textile machines. Custom shapes and patterns can be accommodated upon request for specialized requirements.Q: Are ceramic eyelets, bushes, and rings suitable for high-temperature environments?

A: Absolutely, these ceramic components are engineered to withstand high temperatures prevalent in textile and winding machines, ensuring reliable and stable performance even under intense operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

TROPHY TECH INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |