Tungsten Carbide Coil Winding Nozzle

Product Details:

- Capacity High Precision Guiding

- Diameter Available from 0.2 mm to 2.5 mm

- Pattern Dimensions Varies as per coil winding machine

- Surface Treatment Polished Finish

- Pressure Standard Pressure Use

- Operating Pressure Atmospheric

- Product Type Coil Winding Nozzle

- Click to View more

Tungsten Carbide Coil Winding Nozzle Price And Quantity

- more than 2 Unit

- Tapered (as per image)

- Extremely High

- Ra 0.05 m

- Guiding Nozzle

- 1.0 mm to 6.0 mm

- Coil winding machines, Electronics Industry

- 92-93 HRA

- Long Service Life

- Excellent

- Dark Grey Metallic

- 0.01 mm

- < 0.01 mm

Tungsten Carbide Coil Winding Nozzle Product Specifications

- Available from 0.2 mm to 2.5 mm

- Customized, available as per requirement

- Coil Winding Nozzle

- High Precision Guiding

- Tungsten Carbide

- Varies as per coil winding machine

- Polished Finish

- Tungsten Carbide

- 0.2-0.5 Kilograms (kg)

- Standard Pressure Use

- Atmospheric

- For Guiding Copper Wire

- Tapered (as per image)

- Extremely High

- Ra 0.05 m

- Guiding Nozzle

- 1.0 mm to 6.0 mm

- Coil winding machines, Electronics Industry

- 92-93 HRA

- Long Service Life

- Excellent

- Dark Grey Metallic

- 0.01 mm

- < 0.01 mm

Tungsten Carbide Coil Winding Nozzle Trade Information

- Bangalore

- Cheque

- 200 Unit Per Month

- 3-4 Days

- Contact us for information regarding our sample policy

- All India

Product Description

Tungsten Carbide Coil Winding Nozzle is required for guiding copper wire while winding of electronic assemblies including transformers or motor structures. It is made of superior quality tungsten carbide material and is appreciated for having smooth & strong structural configuration. This nozzle is perfect to be installed in automatic winding machines assuring their superior performance. Tungsten Carbide Coil Winding Nozzle offered by us is greatly admired to ensure smooth wire traveling without causing any stress during winding operation.

Features

- Concentricity is within 0.01mm

- Assures perfect straightness & stiffness of wire

- Superior wear resistance

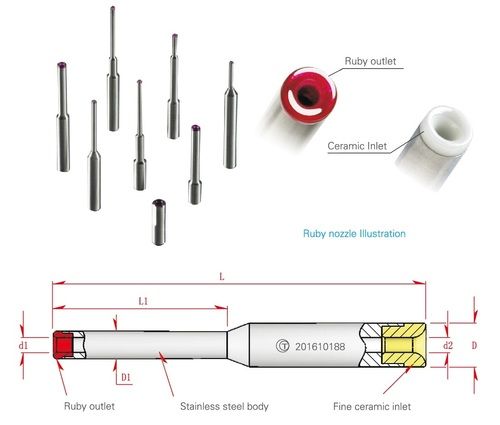

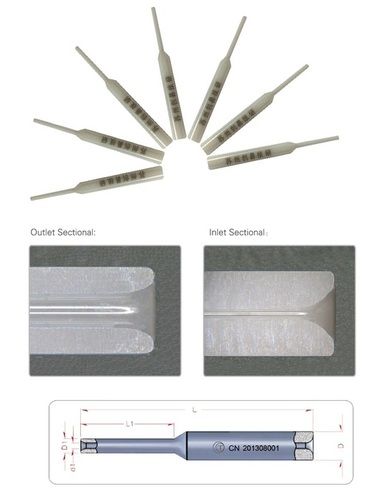

TUNGSTEN CARBIDE NOZZLES (W SERIES)

TROPHY's Carbide nozzles Series is made of tungsten carbide material, with a hardness upto HRA90 and above, and bending resistance up to 2300N/mm. It has an excellent balance between the wear resistance and being too brittle. Each nozzle is made of a solid piece of material with no joints so as to ensure a smooth path for wire travel. The inner bore is ground and polished to Ra0.1. Both the inlet and outlet radii are scientifically calculated and processed to a surface finish ofRa0.025, ensuring smooth travelling and minimal stress to the wire during winding. Concentricity between the clamping diameter and the outlet diameter is0.01mm. The inner bore diameter's tolerance is 0.01mm. It is excellent for precision coil layering.

Advantages

- High impact resistance

- High rigidity

- High hardness

CARBIDE NOZZLE (W SERIES) PART NUMBER GUIDE

Example: W0530-030-0810

"W" - indicates nozzle material is Carbide.

The dimensions of above example is as below (mm):

d1=d2=0.5, L=30, D=3, d1=0.8, L1=10

Manufacturing limitation : d1 to be =0.1mm, D1 to be = 0.3mm

Dimensions

| Item | Part No. | L | L1 | D | D1 | d1 | d2 | H |

| TH2-001 | W0435-2-1010 | 35 | 10 | 2 | 1 | 0.4 | 0.4 | N/A |

| TH2-002 | W0535-2-1210 | 35 | 10 | 2 | 1.2 | 0.5 | 0.5 | N/A |

| TH2-003 | W0435-2-1207 | 35 | 7 | 2 | 1.2 | 0.4 | 0.4 | N/A |

| TH2-004 | W0635-2-1210 | 35 | 10 | 2 | 1.2 | 0.6 | 0.6 | N/A |

| TH2-005 | W0435-2-1007 | 35 | 7 | 2 | 1 | 0.4 | 0.4 | N/A |

| TH2-006 | W0530-2-1210 | 30 | 10 | 2 | 1.2 | 0.5 | 0.5 | N/A |

| TH2-007 | W0330-2-0808 | 30 | 8 | 2 | 0.8 | 0.3 | 0.3 | N/A |

| TH2-008 | W0330-2-0607 | 30 | 7 | 2 | 0.6 | 0.3 | 0.3 | N/A |

| TH2-009 | W0435-2-1508 | 35 | 8 | 2 | 1.5 | 0.4 | 0.4 | N/A |

| TH2-010 | W0635-2-1510 | 35 | 10 | 2 | 1.5 | 0.6 | 0.6 | N/A |

| TH2-011 | W0335-2-0810 | 35 | 10 | 2 | .8 | 0.3 | 0.3 | N/A |

| TH2-012 | W0326-2-1007 | 26 | 7 | 2 | 1 | 0.3 | 0.3 | N/A |

| TH2-013 | W0430-2-1010 | 30 | 10 | 2 | 1 | 0.4 | 0.4 | N/A |

| TH2-014 | W0530-2-1010 | 30 | 10 | 2 | 1 | 0.5 | 0.5 | N/A |

| TH2-015 | W0430-2-1085 | 30 | 8.2 | 2 | 1 | 0.4 | 0.4 | N/A |

| TH2-016 | W0735-2.5-1811 | 35 | 11 | 2.5 | 1.8 | 0.7 | 0.7 | N/A |

| TH2-017 | W08.5-2.5-2011 | 35 | 11 | 2.5 | 2 | 0.8 | 0.8 | N/A |

| TH2-018 | W0330-2-1006 | 30 | 6 | 2 | 1 | 0.3 | 0.3 | N/A |

| TH2-019 | W0635-2-125 | 35 | 15 | 2 | 1.2 | 0.6 | 0.6 | N/A |

TUNGSTEN CARBIDE NOZZLE - TH3 SERIES

| No. | Item | Part No. | Specification (mm) | ||||||

| L | L1 | D | D1 | d1 | d2 | H | |||

| 1 | TH3-001 | W0335-3-1010 | 30 | 7 | 3 | 1.0 | 0.3 | 0.3 | N/A |

| 2 | TH3-002 | W0430-3-1007 | 30 | 7 | 3 | 1.0 | 0.4 | 0.4 | N/A |

| 3 | TH3-003 | W0530-3-1010 | 30 | 10 | 3 | 1.0 | 0.5 | 0.5 | N/A |

| 4 | TH3-004 | W0630-3-1007 | 30 | 7 | 3 | 1.0 | 0.6 | 0.6 | N/A |

| 5 | TH3-005 | W0330-3-0807 | 30 | 7 | 3 | 0.8 | 0.3 | 0.3 | N/A |

| 6 | TH3-006 | W0630-3-1211 | 30 | 11 | 3 | 1.2 | 0.6 | 0.6 | N/A |

| 7 | TH3-007 | W0630-3-1309 | 30 | 9 | 3 | 1.3 | 0.6 | 0.6 | N/A |

| 8 | TH3-008 | W0611-3-1506P | 11 | 6 | 3 | 1.5 | 0.6 | 0.6 | 5 |

| 9 | TH3-009 | W0614-3-1509P | 14 | 9 | 3 | 1.5 | 0.6 | 0.6 | 5 |

| 10 | TH3-010 | W0814-3-1509P | 14 | 9 | 3 | 1.5 | 0.8 | 1 | 5 |

| 11 | TH3-011 | W1014-3-1509P | 14 | 9 | 3 | 1.5 | 1 | 1 | 5 |

| 12 | TH3-012 | W04143-1009P | 14 | 9 | 3 | 1.0 | 0.4 | 0.4 | 5 |

| 13 | TH3-013 | W 1030-3 | 30 | N/A | 3 | N/A | 1 | 1 | N/A |

| 14 | TH3-014 | W0326-3-0808 | 26 | 8 | 3 | 0.8 | 0.3 | 0.3 | N/A |

| 15 | TH3-015 | W0330-3-0810 | 30 | 10 | 3 | 0.8 | 0.3 | 0.3 | N/A |

| 16 | TH3-016 | W0330-3-0607 | 30 | 7 | 3 | 0.6 | 0.3 | 0.3 | N/A |

| 17 | TH3-017 | W03265-3-0811P | 26.5 | 11 | 3 | 0.8 | 0.3 | 0.3 | 15 |

| 18 | TH3-018 | W0626-3-1208 | 26 | 8 | 3 | 1.2 | 0.6 | 0.6 | N/A |

| 19 | TH3-019 | W1030-3-2014 | 30 | 14 | 3 | 2 | 1 | 1 | N/A |

| 20 | TH3-020 | W1230-3-2514 | 30 | 14 | 3 | 2.5 | 1.2 | 1.2 | N/A |

| 21 | TH3-021 | W0330-3-0707 | 30 | 7 | 3 | 0.7 | 0.3 | 0.3 | N/A |

| 22 | TH3-022 | W0330-3-0502 | 30 | 2 | 3 | 0.5 | 0.3 | 0.3 | N/A |

| 23 | TH3-023 | W0626-3-1208 | 26 | 8 | 3 | 1.2 | 0.6 | 0.6 | N/A |

| 24 | TH3-024 | W0530-3-1210 | 30 | 10 | 3 | 1.2 | 0.5 | 0.5 | N/A |

| 25 | TH3-025 | W0330-3-0504 | 30 | 4 | 3 | 0.5 | 0.3 | 0.3 | N/A |

| 26 | TH3-026 | W0825-3 | 25 | N/A | 3 | N/A | 0.8 | 0.8 | N/A |

| 27 | TH3-027 | W0435-3-1211 | 35 | 11 | 3 | 1.2 | 0.4 | 0.4 | N/A |

| 28 | TH3-028 | W03535-3-0811 | 35 | 11 | 3 | 0.8 | 0.35 | 0.35 | N/A |

| 29 | TH3-029 | W0735-3-1411 | 35 | 11 | 3 | 1.4 | 0.7 | 0.7 | N/A |

| 30 | TH3-030 | W0430-3-0808 | 30 | 8 | 3 | 0.8 | 0.4 | 0.4 | N/A |

| 31 | TH3-031 | W1025-3-1608 | 25 | 8 | 3 | 1.6 | 1 | 1 | N/A |

| 32 | TH3-032 | W0845-3-2017 | 45 | 17 | 3 | 2 | 0.8 | 0.8 | N/A |

| 33 | TH3-033 | W1535-3 | 35 | N/A | 3 | N/A | 1.5 | 1.5 | N/A |

| 34 | TH3-034 | W0535-3-1211 | 35 | 11 | 3 | 1.2 | 0.5 | 0.5 | N/A |

| 35 | TH3-035 | W1036-3-2016 | 36 | 16 | 3 | 2 | 1.0 | 1.0 | N/A |

| 36 | TH3-036 | W0630-3-1212 | 30 | 12 | 3 | 1.2 | 0.6 | 0.6 | N/A |

| 37 | TH3-037 | W1022-3-2010 | 22 | 10 | 3 | 2 | 1.0 | 1.0 | N/A |

| 38 | TH3-038 | W0430-3-1510 | 30 | 10 | 3 | 1.5 | 0.4 | 0.4 | N/A |

| 39 | TH3-039 | W0630-3-1511 | 30 | 11 | 3 | 1.5 | 0.6 | 0.6 | N/A |

| 40 | TH3-040 | W0830-3-2010 | 30 | 10 | 3 | 2 | 0.8 | 0.8 | N/A |

TUNGSTEN CARBIDE NOZZLE -TH4 SERIES

| No. | Item | Part No. | Specification (mm) | ||||||

| L | L1 | D | D1 | d1 | d2 | H | |||

| 1 | TH4-001 | W0435-2-1010 | 30 | 15 | 4 | 2.0 | 0.8 | 0.8 | N/A |

| 2 | TH4-002 | W1243-4-2515 | 43 | 15 | 4 | 2.5 | 1.2 | 1.2 | N/A |

| 3 | TH4-003 | W1243-4-2515P | 43 | 15 | 4 | 2.5 | 1.2 | 1.2 | 20 |

| 4 | TH4-004 | W0843-4-2015P | 43 | 15 | 4 | 2.0 | 0.8 | 0.8 | 20 |

| 5 | TH4-005 | W1232-4.5 | 32 | N/A | 4.5 | N/A | 1.2 | 1.2 | N/A |

| 6 | TH4-006 | W1543-4-2512P | 43 | 12 | 4 | 2.5 | 1.5 | 1.5 | 20 |

| 7 | TH4-007 | W0843-3.9-2019P | 43 | 19 | 3.9 | 2.0 | 0.8 | 0.8 | 19 |

| 8 | TH4-008 | W2020-5 | 20 | N/A | 5 | N/A | 2.0 | 2.0 | N/A |

Exceptional Precision and Durability

This coil winding nozzle stands out for its unparalleled precision with straightness tolerance below 0.01 mm and bore concentricity up to 0.01 mm. Manufactured from tungsten carbide, it boasts excellent hardness, extreme wear resistance, and corrosion protection, ensuring continued performance in demanding production environments.

Tailored for Electronic Coil Winding

Specially developed for the electronics industry, these nozzles guide copper wire with high accuracy, supporting complex coil winding processes. The customizable sizes and pattern dimensions ensure seamless integration with various coil winding machine types, optimizing operational efficiency for manufacturers and suppliers alike.

FAQs of Tungsten Carbide Coil Winding Nozzle:

Q: How is the Tungsten Carbide Coil Winding Nozzle used in coil winding machines?

A: The nozzle is installed in coil winding machines to guide copper wire with high precision, ensuring uniform winding and minimizing wire breakage or misalignment during the manufacturing process.Q: What benefits does its ultra-low inner surface roughness provide for wire guidance?

A: With an inner surface roughness of Ra 0.05 m, the nozzle facilitates smooth passage of copper wire, reducing friction and wear, which extends both wire and nozzle service life.Q: When should you consider customizing the nozzles size or pattern dimensions?

A: Customization is recommended when coil winding requirements demand specific nozzle dimensions to fit unique machine setups or wire specifications, ensuring optimal guiding performance and compatibility.Q: Where can this guiding nozzle be sourced in India?

A: It is available from reputable distributors, manufacturers, and suppliers across India, specializing in high-precision tungsten carbide components for the electronics industry.Q: What process does the nozzle undergo for achieving its polished surface finish?

A: Advanced surface treatment and polishing techniques are applied during manufacturing to attain the required smoothness and finish, enhancing corrosion resistance and wire guiding effectiveness.Q: How does the tapered shape of the nozzle benefit coil winding applications?

A: The tapered design assists in precise wire insertion, reduces entry resistance, and aids in accurate alignment, supporting high speed and reliable coil winding operations.Q: What ensures the long service life and high precision guiding capability of the nozzle?

A: Its engineered with high hardness (92-93 HRA), extreme wear resistance, and strict tolerances for straightness and bore concentricity, backed by robust tungsten carbide material and meticulous manufacturing quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Winding Nozzles' category

|

TROPHY TECH INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |